300 mesh grinding mill

bentonite WinnerMac. How to choose suitable bentonite powder grinding machine according to different fineness? When final size is in the range of 100 to 300 mesh, raymond mill...

WhatsApp)

WhatsApp)

bentonite WinnerMac. How to choose suitable bentonite powder grinding machine according to different fineness? When final size is in the range of 100 to 300 mesh, raymond mill...

Nov 16, 2011· The Retsch cutting mill series is used successfully for the efficient preliminary size reduction of a huge variety of materials. ... The new Cutting Mill SM 300 excels especially in .

2 Planetary Ball MillS. Content Planetary Ball Mills – Applications 4 ... They achieve a very high final fineness down to the submicron range. The feed size depends ... 2 500 g x 3 mm ZrO 2 < 300 µm 100 g + 50 ml IPA 1 2 h 450 rpm < 1 µm Sand 500 ml ZrO 2 25 x 20 mm ZrO 2

[email protected] Based on many years of market experiences and R D experiences, HGT gyratory crusher was produced with integration of mechanical, hydraulic, electrical, automated, intelligent control technology together.

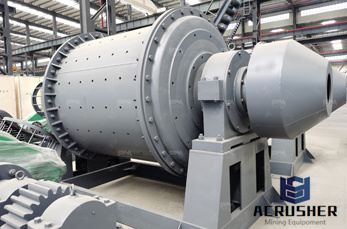

Ball Mill For Zirconium, Wholesale Various High Quality Ball Mill For Zirconium Products from Global Ball Mill For Zirconium Suppliers and Ball Mill For Zirconium ... Get Price. 95% zirconium beads for sand mill ball mill – High ... 95% zirconium beads for sand mill ball mill. Zirconium Beads, ...

The ground sample automatically falls downward – into a drawer for batchwise comminution or via a chute into a larger collection container for continuous operation or directly into a Disk Mill High throughput, high degree of size reduction • Feed size up to 130 mm (BB 300) • High final fineness (d90 < 2 mm)*

Aug 09, 2016· The Cutting Mill SM 300 is suitable for the grinding of soft, mediumhard, tough, elastic, fibrous, and heterogeneous mixes of products. The new Cutting Mill SM 300 excels especially in .

Ball Mills are the most effective laboratory mills for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle size. The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding ...

Raymond mill is effective closedcircuit high fineness powder manufacturing equipment, which is applicated in small and medium mining, silicate and chemical, buildingmaterial, metallurgy, refractory material, pharmaceuticals and lime is a new style powder grinding machine, which is more advanced than ball grinder and much appreciated in many fields due to its domestic leading ...

ball mill 300 kgh final fineness 2 mm. Ball Mill price, ball mill for sale, ball mill specification ... From here,you can get the introduction of ball mill, working ... the powder is discharged by output material board and the final products are wide belt sanding machine. ramesh ji baewar ball mill manufacturer. Read more

Disk, hammer, mortar, planetary ball, rotor, and cutting mills are available to achieve coarse, midrange, and fine results, all the way down to the nano range, µm. Cryogenic mills, or freezer mills, are a type of unit that freezes a material prior to reducing its particle size. What to consider when choosing a laboratory mill?

ball mill mm bwadvibe. ball mill material feed size 130 mm final fineness 5 mm Get A Quote sound of a cement ball millhow is gold final product used ball mill 300 kgh final fineness 2 mm ball mill 10 mm grinding mill equipment Discover all the information about the product Ball nose end mill 10 Mill Ball [24/7 Online]

Ball Mills. Planetary Mills . Universal Cutting Mill variable speed rpm. PULVERISETTE 19. Order No. Product details. Description. ... Final fineness (depends on sieve cassette additional sieve sizes available) 6 mm: Feeding: batchwise/continuous:

2 PLANETARY BALL MILLS. CONTENT Planetary Ball Mills – Applications 4 ... Final fineness Catalysts 250 ml ZrO 2 15 x 20 mm ZrO 2 1 20 mm 130 ml 2 min 450 rpm 63 µm ... 2 500 g x 3 mm ZrO 2 < 300 µm 100 g + 50 ml IPA 1 2 h 450 rpm < 1 µm Sand 500 ml ZrO 2 25 x 20 mm ZrO 2

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. The high energy input is a result of an unrivaled speed of 2000 min1 and the optimized jar design.

industrial crusher 4000 kgh tourdesignersin industrial crusher 4000 kgh tutto inox, capacit 4000 kg/h Free Quote pre20 tons per hour screens mesh south africa talc medium impact crushers vs cone crusher free stone crusher business plan samples pdf grinding mill cement plant in chinese slag crushing machine manufacturer india rotary dryers with ...

Mixer Mill MM 500. MM500 is the first mixer mill in the market to provide a real alternative to grinding in a planetary ball mill – with more comfortable handling and less warming effects. It is a versatile benchtop unit which has been developed specially for dry, wet and cryogenic grinding of up to 2 x 45 ml sample material within seconds.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features. Because these cookies are strictly necessary to deliver the website, refuseing them will have impact how our site functions.

Planetary Ball Mills are used wherever the highest degree of fineness is required. Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processes. The extremely high centrifugal forces of the Planetary Ball Mills result in .

Read more. Manual For 7 Symon Cone Crusher · ball mill 300 kgh final fineness 2 mm · hp400 cone crushers instruction manual · diagram of hydraulic system in crusher · price Mineral Crushing Plant Manganese Steel Roll Mill Crusher Buy. as secondary crusher, our cone crusher which includes CS cone crusher, hydraulic.

A ball mill efficiently operated performs a wide variety of services. In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the SteelHead Ball or Rod Mill will take up to 2″ feed and grind it to the desired fineness. In larger plants where several stages of coarse ...

The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

RETSCH ball mills are available as mixer mills as well as planetary ball mills. Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction. They are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA recovery. RETSCH''s innovative Planetary Ball Mills meet and exceed [.]

The following selection guide provides an initial overview of the application areas of RETSCH laboratory mills and crushers. The selection of a suitable mill depends on the individual application.

WhatsApp)

WhatsApp)